Acoustic Imaging Inspections

Pinpoint air leaks and detect partial discharge without shutting down operations.

Applications Include

.webp?width=150&height=150&name=Compressed%20Air%20Leaks%20and%20High%20Pressure%20Valves%20(1).webp)

.webp?width=150&height=150&name=Compressed%20Air%20Leaks%20and%20High%20Pressure%20Valves%20(1).webp)

Why Acoustic Imaging?

Acoustic imagers are able to identify abnormal sound patterns, ideal for detecting compressed air and gas leaks. They are also great for detecting electrical distribution system issues like partial discharge and corona effects.

- Prevent Costly Failures

- Minimize Downtime

- Lower Operational Cost

- Improve Equipment Reliability

- Identify Safety Hazards

- Non-invasive Inspections

- Reduce Maintenance

- Environmental Compliance

Inspection Process

Our inspection process is designed to be thorough and efficient, with little to no interruption to your operations.

Our team works efficiently to minimize any disruption to your daily operations. We understand that downtime is costly, so we offer flexible scheduling options and tailor our approach to meet your specific needs/ operational constraints.

1) Daytime inspections

2) After-hours evaluations

3) Assessments aligned with planned maintenance

This adaptability ensures thorough inspections while minimizing disruption to your operations.

Our technicians are highly trained and qualified professionals, ensuring exceptional service.

- Certified Thermographers: Level II or III certified professionals with extensive experience in industrial applications. They are trained to not only capture thermal images but also to interpret them in the context of your specific equipment and processes

- Acoustic Imaging Specialists: Experts trained in the latest acoustic leak detection and partial discharge identification techniques. They are skilled in using our advanced acoustic cameras and interpreting the results.

- OGI Technicians: Specially trained in the operation of optical gas imaging cameras and interpretation of results. These technicians are often certified in hazardous area operations, ensuring safe inspections in potentially explosive atmospheres.

We provide a comprehensive reports, detailing all findings and recommendations, at the end of each inspection. Our reports are designed to be both thorough and accessible, providing you with actionable insights, and our technicians are always happy to go over them with you to answer any questions.

Long-term Contracts Module

Long term contracts allow for trend analysis over time, providing deeper insights into asset performance and degradation patterns, not to mention favorable pricing and priority scheduling. Plus, with a long term contract, we can help you develop and implement a holistic inspection plan that aligns with your maintenance strategies, shutdown schedules, and budgetary considerations.

- 1 Year

- 3 Year

- 5 Year

Who We Help

We cater to a diverse range of industries that demand precision and efficiency in their operations.

- Manufacturing

- Electrical Utilities

- Oil & Gas

- Commercial Property Management

- Distribution and Logistics

- Waste Management

- And More

Featured Case Studies

Other MSAI Inspection Services

Motor Circuit Analysis

Motor Circuit Analysis is a de-energized testing method that diagnoses motor health by identifying issues like winding faults, rotor damage, and insulation degradation, helping prevent costly downtime and extend motor life.

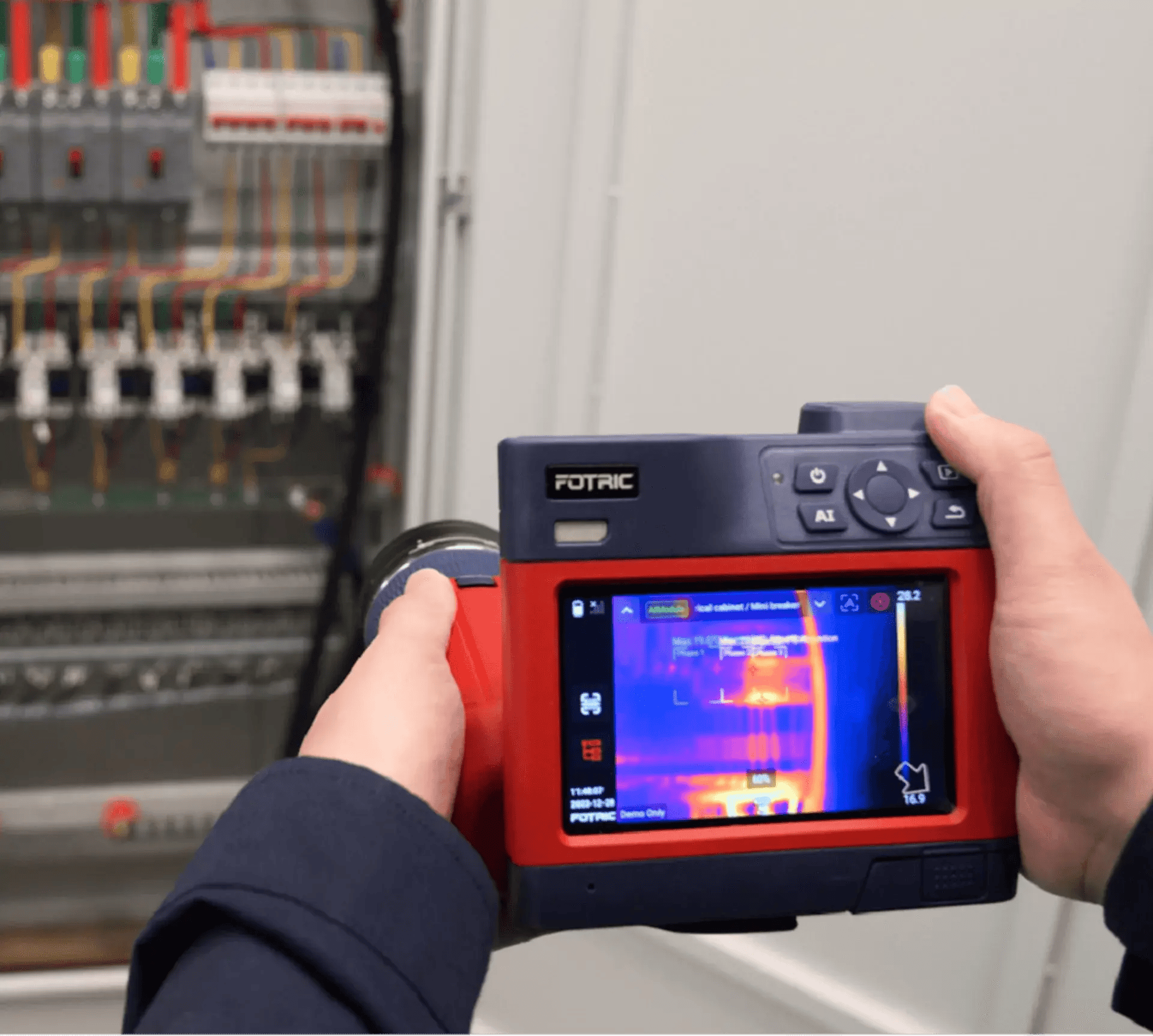

Thermal Imaging

Thermography inspection services enhance predictive maintenance strategies by identifying thermal anomalies, indicative of future equipment failures and/or inefficiencies. Identifying emerging issues early through non-invasive inspections, helps prevent unexpected downtime and costly repairs.

Contact MSAI Inspection Services

Reach out today! Our expert technicians are always happy to answer any questions you might have.